Hamburg, DE

Amandus Kahl

About the company

We plan, design, and build machines, complete plants, and turnkey production facilities for processing, conditioning and pelleting of many different products for a wide variety of industries.

Hamburg, DE

We plan, design, and build machines, complete plants, and turnkey production facilities for processing, conditioning and pelleting of many different products for a wide variety of industries.

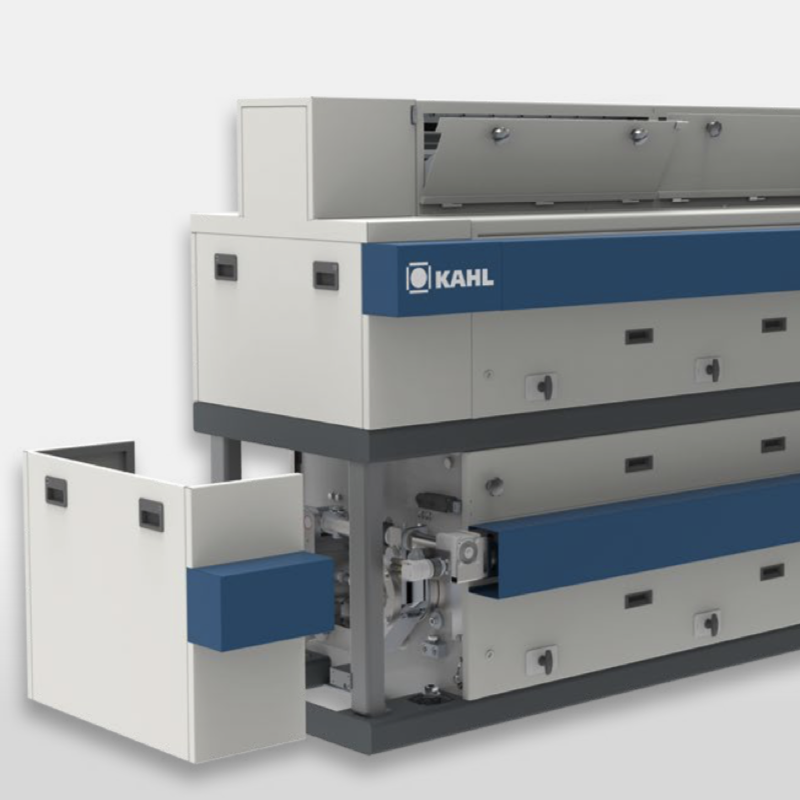

The structure of the animal feed is important for a successful animal nutrition. Our crushing roller mill is used to obtain a homogeneous and high quality feed structure. Its rollers break the feed into small and uniform particles so that a coarse granulate is produced instead of a mealy product. The counter-rotating crushing rollers are provided with a "sharp to sharp" corrugation and have different speeds so that a cutting effect is obtained instead of a crushing effect. The speed of the rollers and the grinding gap can be adjusted during operation. Our crushing roller mill WSB is very appropriate for grain and other feed components. - Significantly lower energy consumption (kWh/t) compared to hammer mills - No aspiration required, thus no moisture loss in the product - Automatic gap adjustment and various differential speeds between the rollers possible - Wide variation of granulations with individual drive, the right particle size for every animal age - More benefits for animal health, animal welfare and higher growth efficiency